In industries where precision, hygiene, and contamination control are paramount, cleanrooms are not just a luxury—they are an operational necessity.

Sectors such as pharmaceuticals, biotechnology, electronics manufacturing, aerospace, and medical devices rely heavily on environments that minimize contamination from dust, microbes, and chemical vapors.

To achieve such stringent standards, many companies turn to full-service cleanroom providers.

But what exactly does a full-service cleanroom company offer, and what should you expect when engaging one?

This article explores the core services, expertise, and advantages that a reputable full-service cleanroom company should deliver.

Comprehensive Cleanroom Design and Planning

A full-service cleanroom company begins its engagement with meticulous cleanroom design and planning.

Cleanroom design is more than arranging walls and air filtration systems; it involves understanding the operational processes, regulatory standards, and environmental requirements specific to the client’s industry.

Key elements include:

- ISO Classification Compliance: Cleanrooms are categorized based on the maximum allowable particles per cubic meter. Companies must adhere to ISO 14644 standards. A full-service provider ensures your facility meets the appropriate class—be it ISO Class 5 for semiconductor manufacturing or ISO Class 7 for pharmaceutical production.

- Layout and Workflow Optimization: Beyond cleanliness, efficient workflow is critical. A reputable company analyzes production processes to design layouts that minimize contamination risks, streamline personnel movement, and optimize material flow.

- Scalable Solutions: Businesses evolve, and so do cleanroom requirements. Full-service providers anticipate future expansion or modification needs, ensuring that cleanroom designs are flexible and scalable.

By engaging experts from the start, you ensure your cleanroom is not only compliant but also tailored to operational efficiency.

Turnkey Installation Services

A hallmark of a full-service cleanroom company is the ability to provide turnkey installation.

This means the company handles everything from materials procurement to final assembly and commissioning.

Expect these services during installation:

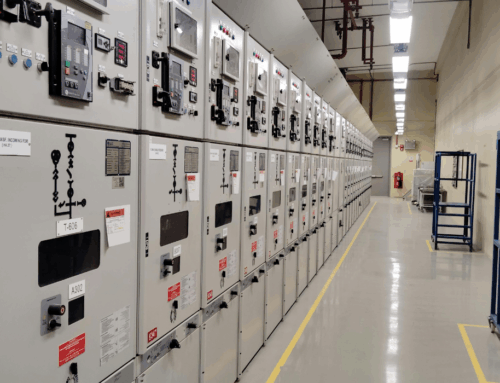

- Construction and Assembly: From modular panels to high-grade stainless steel surfaces, cleanroom construction involves precise installation techniques to avoid contamination during assembly. Full-service providers employ trained technicians who follow strict protocols.

- HVAC and Filtration Systems: Cleanrooms depend heavily on controlled airflow and filtration. High-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters are installed to maintain air cleanliness levels, temperature, and humidity.

- Electrical and Lighting Installation: Specialized lighting and electrical systems are required to meet operational and safety standards while minimizing particle generation.

The advantage of turnkey services is convenience.

You receive a fully functional cleanroom without having to manage multiple contractors or integrate disparate systems.

Regulatory Compliance and Validation

Compliance with industry regulations is non-negotiable for cleanrooms, especially in sectors like pharmaceuticals, medical devices, and food processing.

A full-service cleanroom company guides clients through the often complex regulatory landscape.

Expect these critical services:

- Regulatory Expertise: Knowledge of FDA, cGMP (current Good Manufacturing Practices), ISO standards, and other local and international regulations is essential. Full-service providers ensure your cleanroom meets these rigorous requirements.

- Qualification and Validation: After installation, cleanrooms must undergo testing to confirm compliance with design specifications. This includes Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). Full-service companies perform these tests, document results, and provide certification.

- Ongoing Compliance Audits: Regulations evolve, and your cleanroom must keep pace. Some companies offer periodic audits and updates to maintain compliance and prepare for inspections.

Partnering with a provider knowledgeable in regulatory compliance reduces the risk of costly fines, recalls, or operational downtime.

Cleanroom Equipment and Supplies

A cleanroom is more than a controlled space; it is also a system of equipment and materials that must meet strict contamination standards.

A full-service cleanroom company should provide or source high-quality:

- Air Handling Units and Filtration Systems: As the lungs of a cleanroom, these systems must maintain the appropriate airflow and filtration.

- Cleanroom Furniture and Fixtures: Tables, chairs, storage units, and workstations are designed with materials that resist particle shedding and are easy to clean.

- Gowning Supplies and Consumables: Gloves, suits, masks, shoe covers, and cleaning agents are selected to minimize contamination and meet operational needs.

This integrated supply chain ensures that all aspects of your cleanroom environment are controlled from day one.

Installation of Monitoring and Control Systems

Modern cleanrooms are sophisticated environments requiring continuous monitoring and control.

Expect a full-service provider to include:

- Environmental Monitoring Systems (EMS): Sensors track particulate levels, temperature, humidity, and pressure differentials in real-time.

- Automated Data Logging: Maintaining records for regulatory compliance and quality assurance is simplified through digital monitoring systems.

- Alarm and Response Protocols: If environmental parameters drift outside acceptable limits, automated alerts help prevent contamination before it impacts production.

By installing these systems, companies gain visibility and control over critical cleanroom conditions, ensuring consistent product quality.

Cleanroom Certification and Maintenance

After construction and installation, cleanrooms require ongoing certification and maintenance to sustain compliance and performance.

Full-service cleanroom companies typically offer:

- Routine Certification Services: Periodic testing of airflow, filter integrity, and particulate counts ensures continued adherence to ISO standards.

- Preventive Maintenance Programs: Scheduled inspections of HVAC systems, filters, and equipment prevent unplanned downtime.

- Repair and Retrofitting: When components fail or technology evolves, full-service providers offer repair and upgrade solutions.

A cleanroom is only as effective as its maintenance program, and companies that provide end-to-end support simplify operational management.

Consultation and Training Services

Even the most advanced cleanroom is ineffective if staff do not adhere to proper protocols.

A full-service cleanroom company should provide:

- Staff Training Programs: Personnel must understand gowning procedures, contamination control, and standard operating procedures (SOPs).

- Process Optimization Consulting: Experts analyze workflow and suggest adjustments to improve efficiency while maintaining cleanroom integrity.

- Troubleshooting Support: When challenges arise—such as unexpected particulate levels or equipment malfunction—professional guidance ensures quick resolution.

Training and consultation help organizations maintain compliance, reduce errors, and maximize return on investment in their cleanroom infrastructure.

Customization and Industry-Specific Solutions

Not all cleanrooms are created equal.

Full-service providers excel in tailoring solutions for unique industry requirements:

- Pharmaceutical Cleanrooms: Emphasize sterile conditions, precise humidity and temperature control, and regulatory compliance.

- Electronics and Semiconductor Cleanrooms: Focus on particle-free environments, electrostatic discharge control, and precise airflow.

- Biotechnology and Laboratory Cleanrooms: Require containment protocols for biohazards, specialized ventilation, and advanced monitoring.

A provider with expertise across industries can recommend solutions optimized for both operational and regulatory needs, ensuring maximum efficiency and safety.

Project Management and Coordination

Large-scale cleanroom projects involve multiple disciplines, from architecture and engineering to HVAC and electrical installation.

Expect a full-service cleanroom company to manage the project end-to-end:

- Single Point of Contact: Clients benefit from streamlined communication and accountability.

- Timeline and Budget Management: Experienced providers manage procurement, construction, and commissioning within agreed schedules and costs.

- Coordination with Third-Party Vendors: When specialized equipment or services are required, full-service providers handle vendor management to ensure integration without delays.

This level of project management minimizes disruption to your operations and reduces the risk of miscommunication or delays.

Conclusion

A full-service cleanroom company does more than construct a sterile environment; it provides a complete ecosystem that includes design, installation, regulatory compliance, equipment provision, monitoring, certification, maintenance, and training.

By working with such a provider, organizations gain peace of mind, operational efficiency, and assurance that their cleanroom will consistently meet stringent contamination control standards.

When selecting a full-service cleanroom company, prioritize providers with a proven track record across relevant industries, strong regulatory knowledge, and the ability to offer end-to-end solutions.

The right partner not only builds a cleanroom but also empowers your team with the knowledge and tools to operate it effectively—ensuring that your critical processes remain contamination-free and fully compliant with industry standards.

Investing in a full-service cleanroom provider is an investment in operational excellence, product integrity, and regulatory compliance—a decision that pays dividends in quality, efficiency, and peace of mind.

FAQs

What is a full-service cleanroom company?

A full-service cleanroom company provides end-to-end solutions for cleanroom projects, including design, construction, equipment installation, regulatory compliance, certification, maintenance, and staff training. Essentially, they handle every aspect of creating and sustaining a contamination-controlled environment.

Why should I choose a full-service cleanroom provider instead of multiple contractors?

Engaging a full-service provider ensures streamlined project management, consistent quality, regulatory compliance, and reduced risk of delays or miscommunication. One provider manages all aspects, which is more efficient than coordinating multiple contractors.

What industries typically require full-service cleanrooms?

Industries such as pharmaceuticals, biotechnology, medical devices, electronics manufacturing, semiconductors, aerospace, and food processing commonly require full-service cleanrooms due to stringent contamination control and regulatory standards.

What does cleanroom design involve?

Cleanroom design includes planning layouts for efficient workflow, selecting materials that minimize particle shedding, complying with ISO standards, and incorporating scalable solutions for future growth. It considers operational processes, equipment needs, and regulatory requirements.

What regulatory standards do full-service cleanroom companies follow?

Cleanroom providers adhere to standards such as ISO 14644 for cleanroom classification, FDA and cGMP requirements for pharmaceuticals, and other industry-specific guidelines. They also handle documentation, testing, and validation to ensure compliance.

What is included in turnkey cleanroom installation?

Turnkey installation includes construction and assembly of cleanroom panels, installation of HVAC and filtration systems, electrical and lighting setup, and integration of cleanroom furniture and fixtures. After installation, the room is ready for immediate use.

How do cleanroom companies maintain contamination control?

Contamination control is maintained through high-efficiency air filtration (HEPA/ULPA), controlled airflow, specialized gowning and cleaning protocols, surface materials that resist particle shedding, and continuous monitoring systems.

Do full-service cleanroom providers offer ongoing maintenance?

Yes, most full-service providers offer preventive maintenance, routine certification, repair services, and retrofitting as needed. This ensures the cleanroom continues to meet regulatory standards and perform efficiently.